Electric Arc Furnace (EAF)

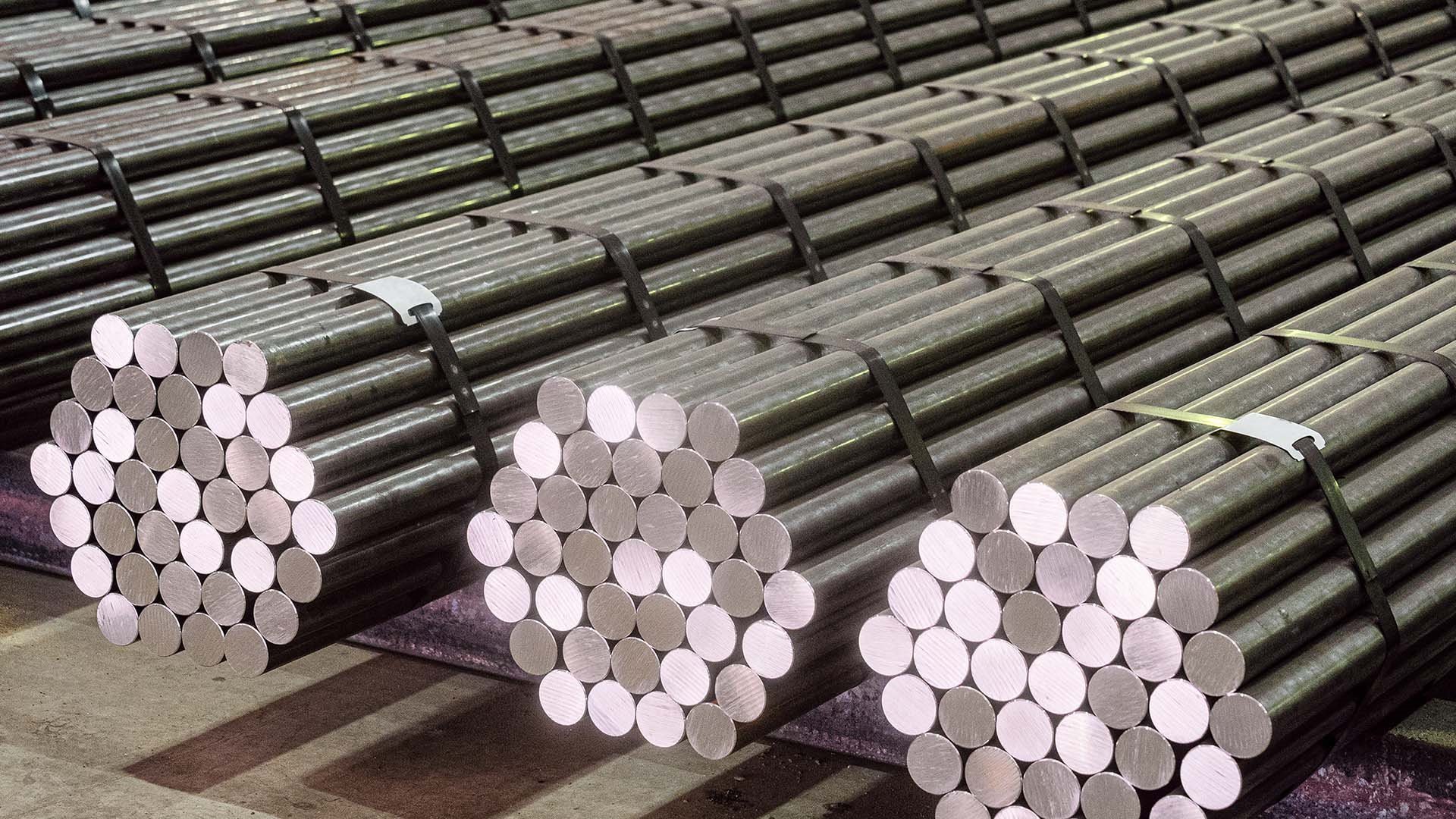

Scrap iron and scrap substitutes, such as direct reduced iron (DRI), are converted into steel in an electric arc furnace (EAF), using the heat from an electric current.

Market Needs

The turbulence of boiling molten steel and the electric arc can cause refractory wear, such as erosion, which results in shortened refractory life. Maintaining slag foaming for a long operation is crucial to prevent such damage.

Solutions

Quicklime

- Remove impurities, such as silica, alumina, iron oxide and sulfur

- The foaming slag is formed for an extended arc operation, which protects refractory from turbulence and electric arc